In 2019, renewable energies generated around 11% of global electricity consumption. This percentage is increasing. Within them, hydroelectricity accounted for 78%, wind power 10%, geothermal also 10% and biomass and solar 1%.

Wind turbines for wind power are very bulky elements. Currently, wind farms are being installed in the sea (offshore) whose blades reach at their highest point almost 200 meters above the base of the mast.

Both in the manufacture of the blades, as in the rotors and multipliers, the handling of bulky and heavy parts and work at height is required, for which we design and manufacture a variety of solutions.

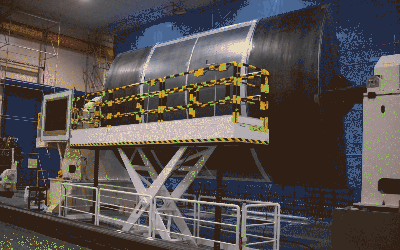

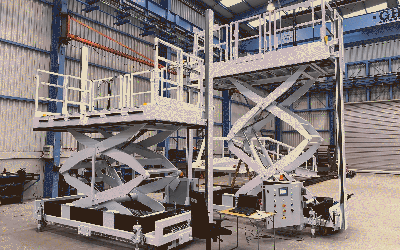

On the other hand, Eyher lifting platforms allow operators to access the entire perimeter of the blades, or large rotors, in an ergonomic and safe way, thanks to adapted profile designs, removable balconies and telescopic rails.

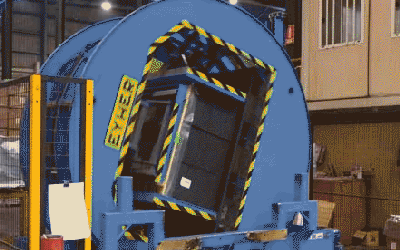

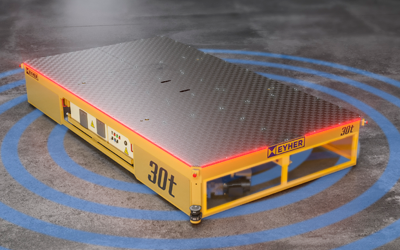

Our motorized cars are used both for the movement of the blades themselves from one process to another, and to transport multipliers to dimensional control cabins or complete large nacelles. Likewise, we manufacture turners to manipulate the multipliers, crowns or elements of the nacelle in its production process.

All our solutions have remote connectivity and can be integrated into the control of more complete installations, as well as recording operating data in the cloud.

At Eyher, we custom design and manufacture all types of machinery for companies in the wind sector, following the specific needs of each client and our more than 65 years of experience in the wind industry.