Home / Load dumpers

Load dumpers

Customised Industrial Load Turners

Dumping of large loads safely in the foundry of the available area and the method of loading and unloading.

Consult load dumpers:

DUMPERS

Technical sheet

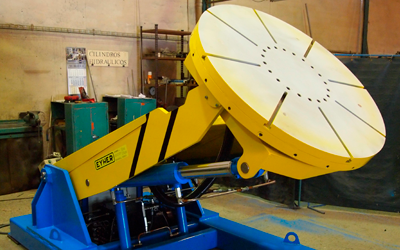

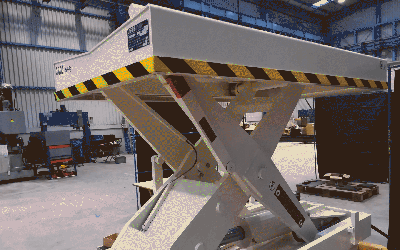

Load capacity: up to 100.000 kg.

Platform dimensions: as especified

Positioning of the tipper: resting on the ground

Loading and unloading: Pon the same side or on opposite sides.

Drive: electromechanical with brake motor-reducer, sprockets and chains; and by group, motor and hydraulic cylinders.

Maneuver: electrical maneuver according to EN 60204-1 in a cabinet with a padlockable main switch. Start and stop buttons, magneto-thermal circuit breaker, etc. With maintained action control buttons and emergency stop button.

Security: safety photoelectric barriers and mirrors to protect all loading and unloading sides.

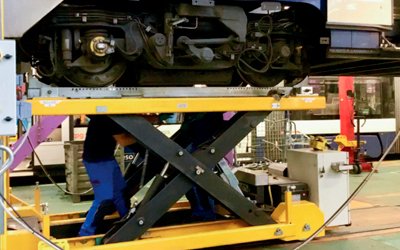

Eyher puts at your disposal the range of solutions for turning loads. With this we achieve an improvement in safety for people and loads, avoiding dangerous maneuvers with cranes and forklifts.

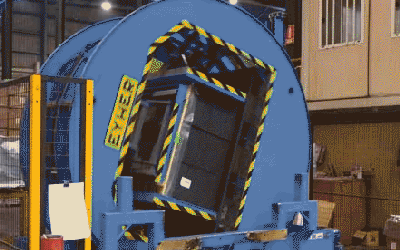

Industrial load dumpers

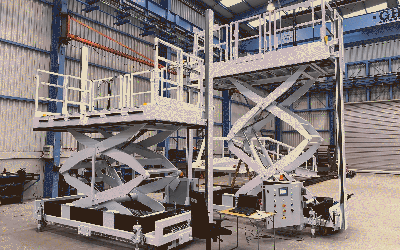

There are different types of turners depending on the load, the necessary turning (90º, 180º) and the space available for the operation:

- Electromechanical turners for turning at 90º.

- Hydraulic tilters for turning at 90º.

- Electromechanical turners for 180º turning with loading and unloading on opposite sides.

- Electromechanical turners with rotation to turn 180º and load and unload on the same side.

Tailor-made load dumpers

EYHER studies each application, need, available space, security and work methodology to offer the tailor-made load dumper suitable for each need. To do this, it has qualified personnel in mechanical and electrical engineering and machine safety.

OTHER OPTIONS

Industrial uses of load dumpers

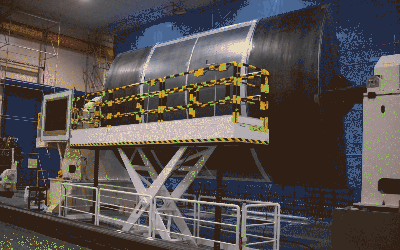

/ Flip and change pallets

One of the main uses of industrial tippers is the turning and changing of pallets . The turner contains a pressure system to fix the packages of sheets. It also incorporates a rotating lower frame for loading/unloading packages on the same side. The machine can also include fixed racks for better support of the pallet.

The sheets are loaded into the turner with 2 pallets, the original at the bottom and the new one at the top. The loading/unloading operation can be done with a forklift or crane.