Home / Industrial Elevators

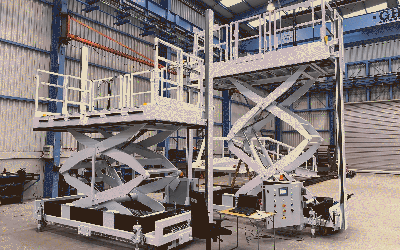

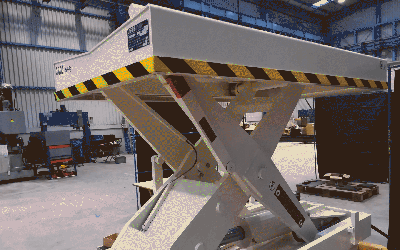

Industrial Elevators

Hydraulic or electromechanical for special needs in industrial buildings with characteristics that require a customized solution.

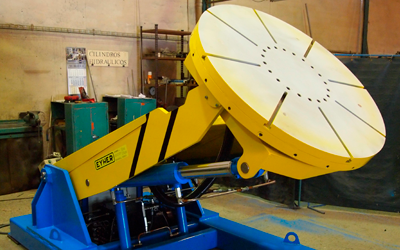

INDUSTRIAL ELEVATORS

Technical sheet

Load: Up to 40.000kg

Dimensions: as specified

Lifting stroke: Up to 10.000 (A-mm)

Minimum height: 500- 1.200 (B-mm)

Options: Hydraulic, electromechanical, simple and double scissors.

Lifting system: By means of scissors activated by a complete electro-hydraulic group, with electric motor (IP-55), pump, tank, solenoid valves, etc.

Our industrial elevators, screw or scissor (hydraulic elevators), allow to adapt to the available space , and to concrete or metal structures, since they are platforms that have their own gantries that support the entire lifting structure.

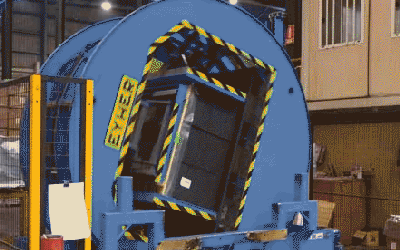

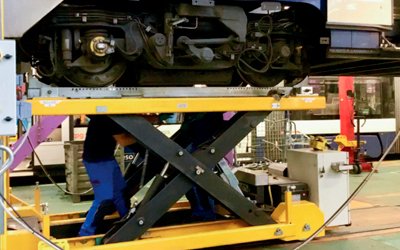

Industrial Trucks Elevators

Eyher industrial elevators have the following characteristics:

- Oil collection system in a hydraulic group that prevents spills on the pavement during any of the operations. Removable and accessible for cleaning and removal of oil.

- Cylinders with hard chrome rod.

- Joints with self-lubricating bearings.

- SEW motor-reducer-brake drive, + MAYR electromagnetic safety brake + vertical spindle with load nut + 80/20 diameter safety nut.

- Variable speed drive for progressive starts and stops.

- Constant speed descent regulator.

- Charge maintenance in case of power outage.

- Fall arrest system according to EN 280.

- Load control system at the entrances and throughout the lifting stroke

- Platform with non-slip floor, pe tear plate.

Tailor-made forklifts

Eyher designs, manufactures and installs custom industrial elevators. To do this, it analyzes each need based on the work to be carried out and the available space and reviews the information on similar projects carried out previously, as well as all issues related to certificates and machine safety to offer the solution that best suits each case.

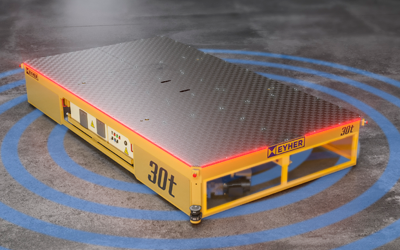

OTHER OPTIONS

Industrial uses of industrial elevators

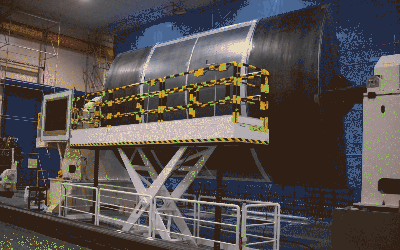

/ Transport Big Bags

Within the production process, industrial elevators can be used to lift pallets with big-bags of raw material from the lower floor of the plant to an upper floor.

To do this, with the help of a chain elevator, pallets with big-bags are passed from one floor to another and a roller path buffer on each floor to be able to store up to 3 pallets and, in this way, optimize cycle times.