Home / Lifting tables / Electromechanical Lifting table

Electromechanical Lifting table

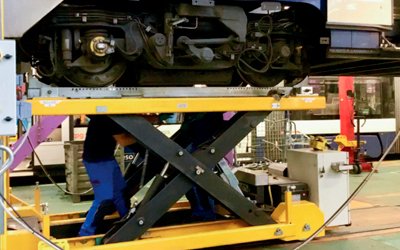

Lifting loads in automated processes that require precision and the absence of hydraulics.

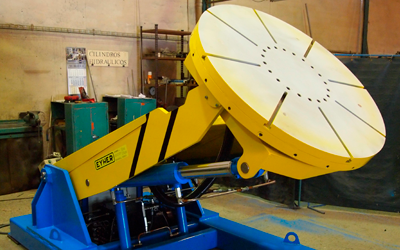

ELECTROMECHANICAL LIFTING TABLE

Technical sheet

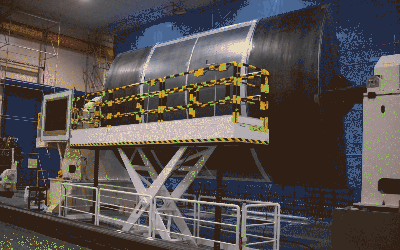

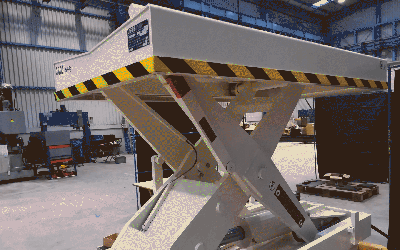

Lifting system: by means of scissors operated by motor-reducer-electric-brake, spindle, nut, etc.

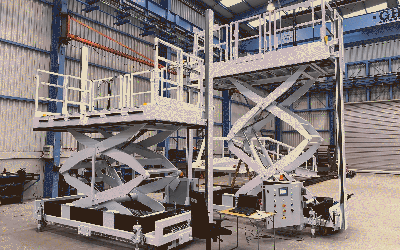

Scissors: simple, double or triple

Load capacity: 20 kg – 50 t

Lifting stroke: 1m – 15m.

Management: electrical maneuver and keypad, or PLC programmable and integrated into general control.

Blocking system: blocking system for the lowering of the table in case of power failure.

Others: stop safety frame, blocking bars for maintenance and lifting and lowering limit switch.

At Eyher we specify, design and manufacture oil-free electromechanical lifting tables for clean room applications or those that require precision work and/or intensive use not achievable with hydraulic configurations.

Electromechanical scissor tables

Our electromechanical tables have a lifting system using scissors operated by motor-reducer-electric brake (IP-55), spindle, nut, etc.

In addition, they have an electrical maneuver according to EN 60204-1 in a cabinet with a pad lockable main switch, start and stop pushbuttons, magnetothermal circuit breaker, etc., as well as a pushbutton panel with man present pushbuttons, emergency stop pushbutton and system platform lowering lock in case of power failure.

Custom electromechanical lift tables

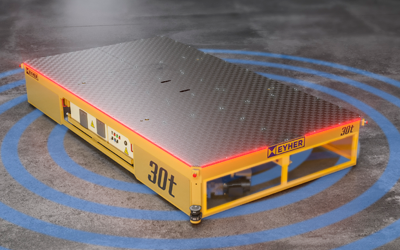

Eyher offers capabilities for the specification, design, manufacture and installation of custom electromechanical scissor tables , as well as personalized post-sale service according to the needs of each client.

In addition, Eyher has the necessary calculations and experience that allows the parameterization of the equipment based on the efforts applied to the electromechanical element, the power and torque of the gearmotor, and the placement of the different joints to be placed on the connecting rods of the lifting table.