Home / Lifting tables / Belt Lifting table

Belt Lifting table

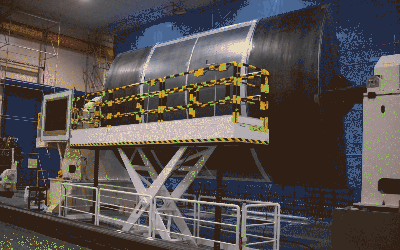

Lifting loads in automated processes that require precision, speed, and intensive use.

BELT LIFTING TABLES

Technical Sheet

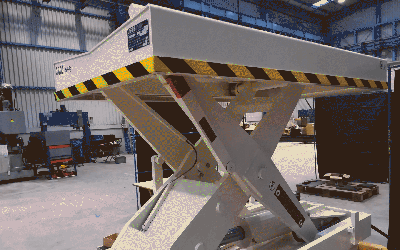

Lifting system: by means of scissors driven by a reduction motor, electric brake, and straps.

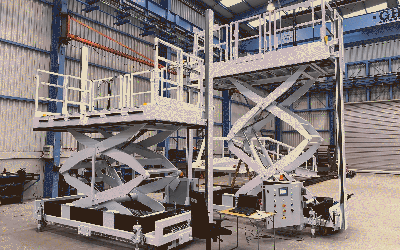

Scissors: Simple, double o triple.

Load capacity: 20 kg – 10 t

Lifting stroke: 1m – 15m.

Management: electrical maneuver and keypad, or PLC programmable and integrated into general control.

Blocking system: blocking system for the lowering of the table in case of power failure.

Others: stop safety frame, blocking bars for maintenance and lifting and lowering limit switch.

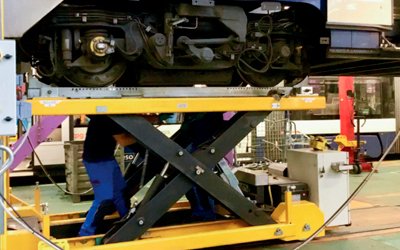

At Eyher we specify, design and manufacture belt lifting tables as an alternative to hydraulic tables. The belt system allows speeds much higher than alternative electromechanical and hydraulic systems, in addition to facing intensive use and high stopping precision.

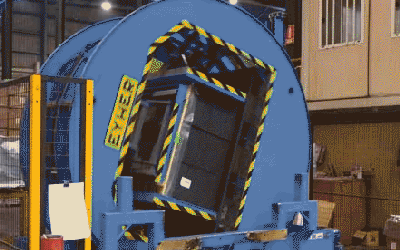

Industrial Belt Lifting Table

It is a very versatile type of lifting belt table, eco-efficient as it does not use oil and allows intensive work at different working heights and high speeds.

These types of needs are very common in automotive assembly lines, where the chassis of the different vehicles must be raised quickly and precisely for the work of the different operators or welding and riveting robots.

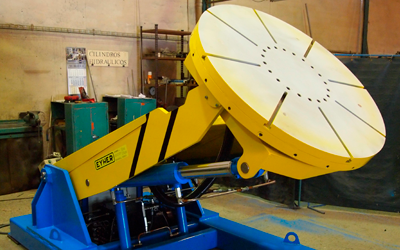

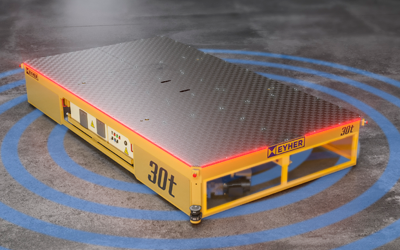

Belt Lifting table tailor made

Eyher offers capabilities for the specification, design, manufacture and installation of bespoke belt lifting tables, as well as personalized after-sales service according to the needs of each client.

EYHER has the necessary calculations and experience that allows the parameterization of the equipment based on the efforts applied to the belt, the power and torque of the gearmotor, and the placement of the different rollers to be placed on the connecting rods of the lifting table.